Our Workshop

File work "Guillochage"

All our springs are hand filed and have a blade-stop system. We do not make cheap industrial welded bee springs either

All the bees of our knives are forged (no cheap welded springs at Fontenille Pataud) and filed twice : 1st file work before assembling and 2nd before final quality inspection and checking

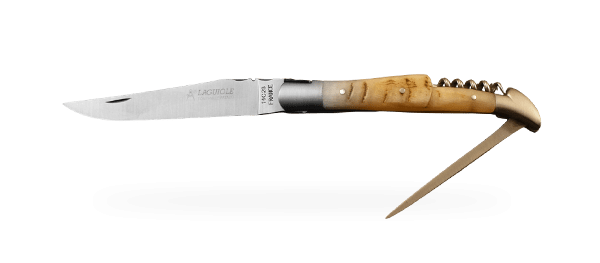

Here is what the final product looks likes

Selection and spare parts work

All our blades are finely and carefully polished by a team of skilled workers (with buffalo grinding wheels) to guarantee top quality products. Our trademark Gilles® stands for quality of workmanship and commitment to excellence

Bolsters are meticulously filed to guarantee a perfect fit with the knife handle

Drilling carrefully and precisly the forged springs

Drilling the olive wood handle before knife assembling

Selection of handles

All scales are carefully selected to make sure they match as much as possible

How we assemble the handle. From right to left : Rectangular scale with shepherd's cross / outline grinding / first shaping and polishing

Laguiole Making of handles

Individual adjustment of each scales

Rectangular scales are worked on the wheel until getting the desired shape

Assembling & bench working

We take particular care in making perfectly solid knife (no play at all)

Sharpenning the knife blade

All our knife blades are sharpened by skilled craftsmen. High quality steel and thorough polishing make the blade very sharp and easy to sharpen later on

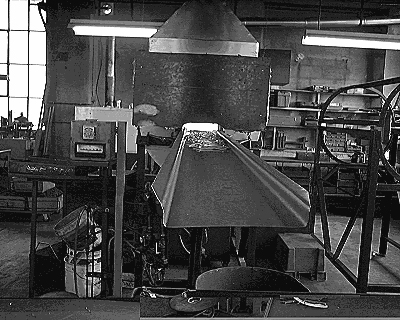

Heat Treatment

Blades, springs, corkscrews etc.. are made from various type of steel ; each having its own hardening treatment (oil, water, temperatures)

Heat treatment process is applied to blades and springs to give them strength and elasticity; then, hardness is checked. Swedish Sandvik stainless 12c27 steel blades are 56 Hrc controlled. Our latest blades, made from RWL 34 special powder stainless steel are hardened to 60Hrc

Engraved spring

Personalized engraving on the knife sring